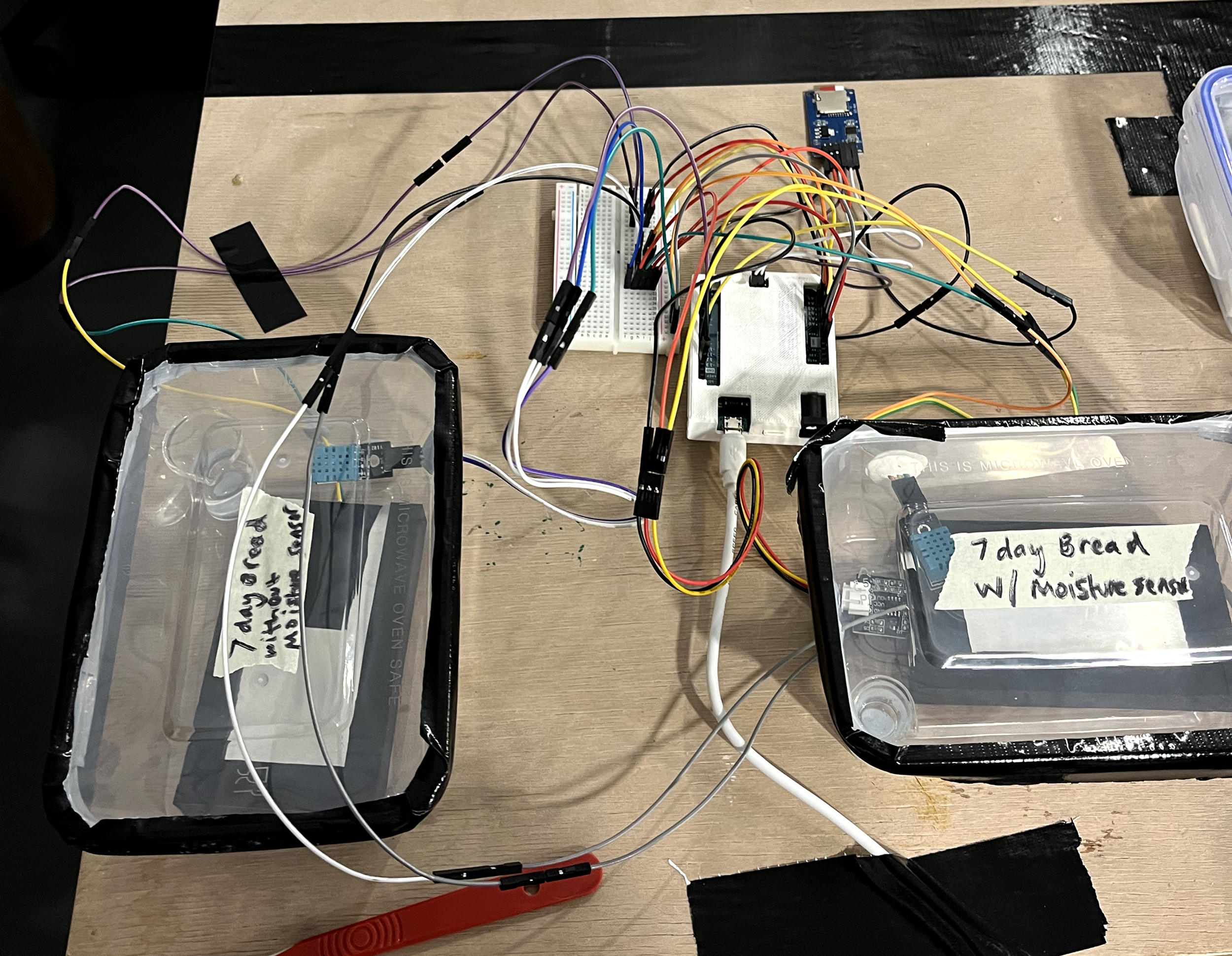

So how is the Modulo sensor used in a real home? First, during a renovation, it can be easily adhered to a specificed number of walls, just like wallpaper. The Modulo Box, which fits discreetly on a skirting board, powers the sensor with batteries, and sends raw capacitance readings to the cloud every 30 minutes. A specially specially designed user interface, called the Interaction Cube, turns red if mould is detected, and blue to motivate the tenant to improve ventilation. Finally, for landlords, we created a web app for viewing the real time status of their properties remotely.